ASTM G75-15 – Miller test

Millertest ASTM G75-15

The Millertest allows investigations of the abrasiveness of solid-liquid mixtures. The result of the miller test is the Miller number, which allows a statement to be made as to whether special precautions must be taken to protect against wear or not. The Miller test is defined in the ASTM G75-15 standard. This test is one of the few tests in the field of wear that can be easily compared internationally, as this standard has become widely accepted. The test can be designed in two directions. Either standard samples or a standard mixture is used. Standard samples determine the abrasiveness of the mixture, while standard mixtures allow the wear resistance of the sample to be determined. The great advantage of this test method is its versatility with regard to the composition of solid and liquid. The ISAF usually uses a standard mixture.

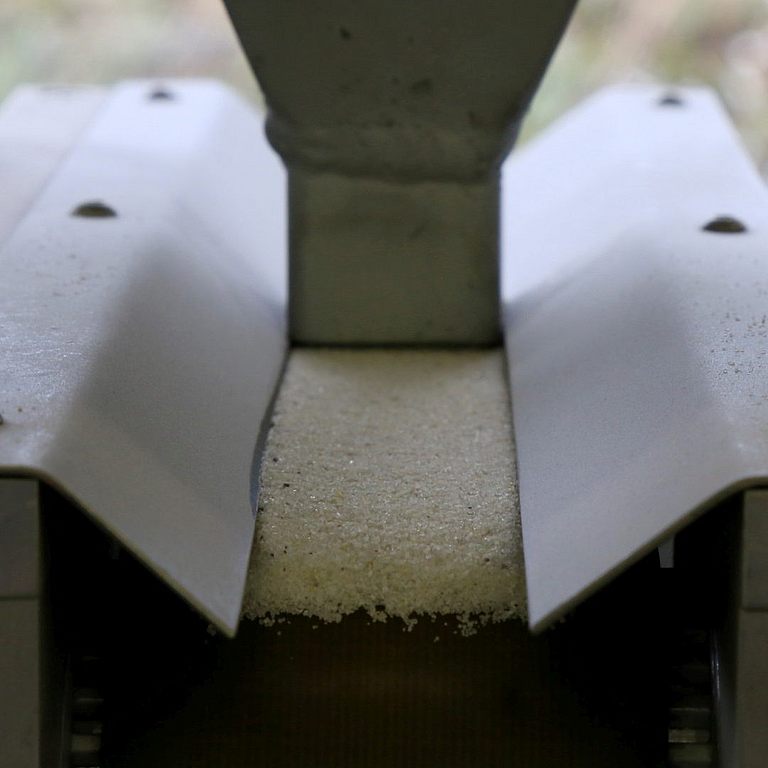

For the miller test, the wear samples are clamped in the sample holders and then immersed in a trough containing the solid-liquid mixture. The rotor, driven by a motor, ensures an oscillating movement of the samples through the eccentrically mounted drive rod, Figure 1. The amount of liquid in the troughs is so large that the samples are not heated by friction. Deviations from the normal test are possible after consultation with regard to the slurry and the sample material.