ASTM B611-13 - Friction wheel test

Friction Wheel Test ASTM B611-13

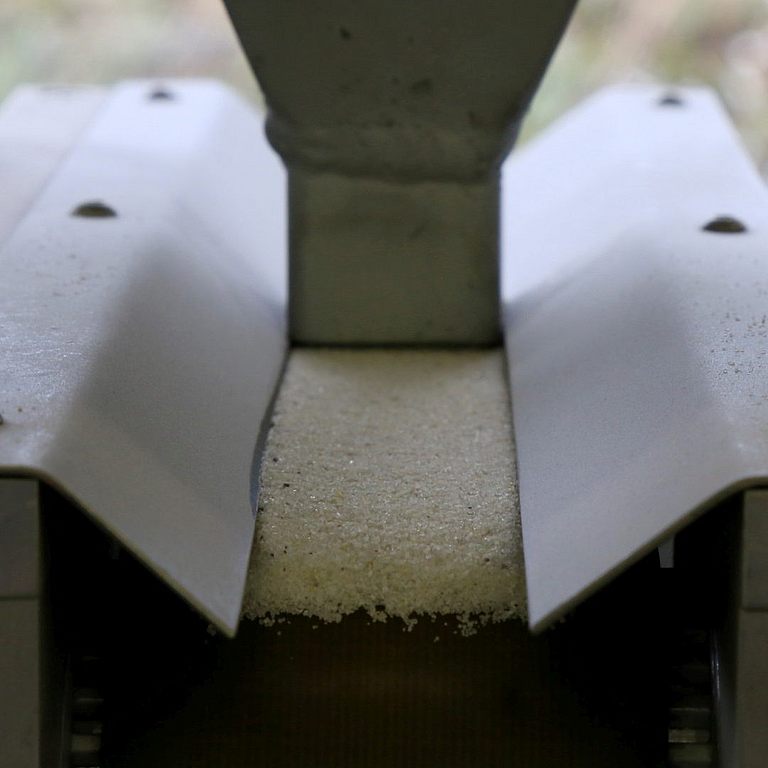

This test method, standardised according to ASTM B611-13, has its origin in the testing of hard metals for mining applications. The facility at ISAF has been designed and constructed according to the specifications described in the standard. Here, a hardened steel wheel is driven at a defined speed over the test period. The sample is pressed against the wheel with a normal force. The rotating steel wheel serves as a carrier for the abrasive agent which is transported from a sump in the lower part of the container directly into the contact zone with the test specimen, Figure 1.

The mixture consists of normal corundum and water. This method can be used for testing hard deposit welds as well as high hardness materials (hard metals, wear protection layers, tool steels, hardened or tempered materials, PM materials etc.) due to the high local abrasive stress. The evaluation is usually gravimetric, the material removal is given in mm³. Modifications in normal force, sample geometry and abrasive material are also possible on request and will be marked as such.