Pin-on-Roll and Roll-on-Roll test

Pin-on-Roll and Roll-on-Roll experiment

For investigations of adhesive wear, ISAF offers tests with a non-standardised test rig. Here the test pieces are pressed against each other with a constant normal force. The roller fixed to the drive shaft is driven at a constant speed. The test stand can be operated in a temperature window from room temperature to 900°C, depending on the design. Dry or lubricated friction contact can also be selected. During the test, the speed is monitored and the torsional moment of the drive shaft is recorded, Figure 1. This allows online recording of the friction coefficient µ. The specimens are weighed before and after the test and thus the material transfer is determined. Surface examinations can also be carried out to better assess adhesion damage.

Pin-on-Roll test

In this arrangement, for which two different test stands are available, a cylindrical test piece or a test piece adapted to the roller (friction partner B) (friction partner A) is pressed against body B. In this test arrangement, the maximum test temperature is 650°C with a dry test set-up. The maximum friction speed is 4 m/s, the load can be up to 250 N in the standard set-up. However, loads of 700 N can also be realized with a special set-up.

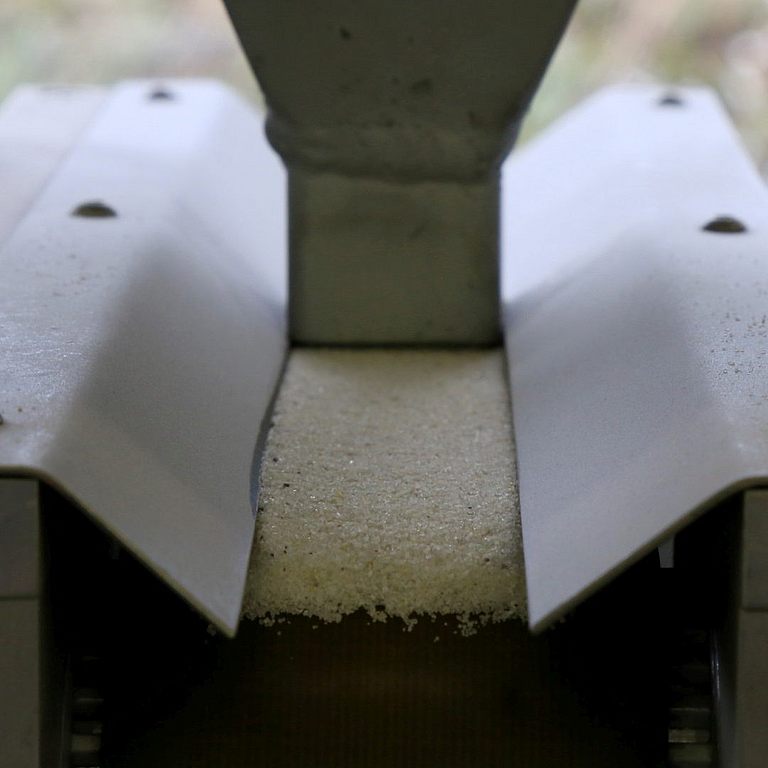

Roll-on-Roll test

In this case, both friction partners are rollers, Fig. 3, and both shafts are driven via a gearbox with a transmission ratio of 1. If slip is to be simulated, this is done by changing the diameter of one of the friction partners. This test arrangement allows test temperatures of up to 900°C, with dry running. For lubricated contact, room temperature applies, as with pin/roller.