ASTM G32-16 - Cavitation Test

Cavitation test according to G32-16

Studies on vibration-induced cavitation loading are carried out at ISAF in accordance with the ASTM G32-16 standard.

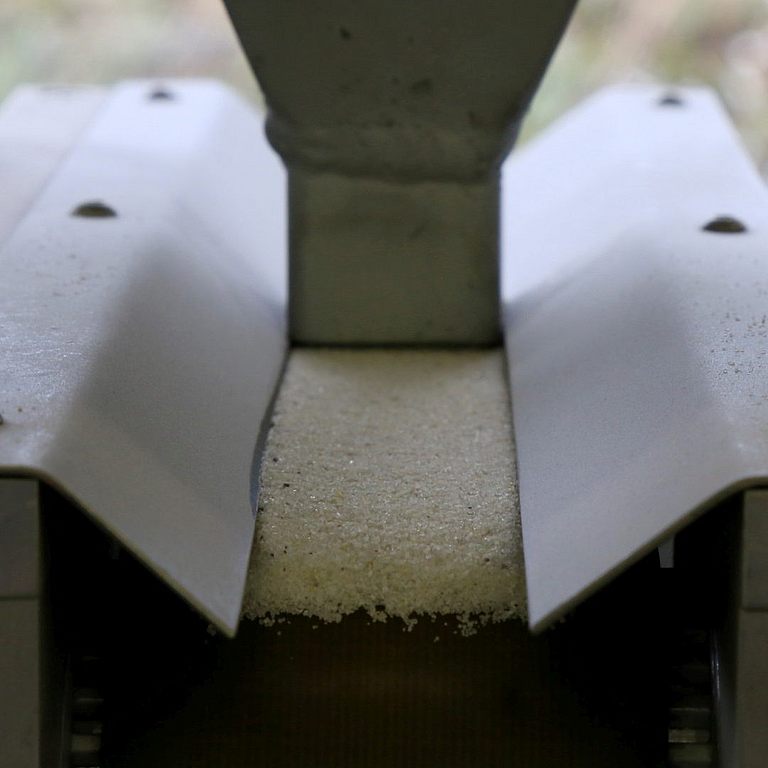

The main components of the test bench (Fig. 1) are

- Ultrasonic generator

- piezoelectric transducer

- Transformer

- Sonotrode (body and tip)

Materials can be tested by direct and indirect methods. In the direct method, the sample material is screwed onto the sonotrode as a tip. In the indirect method, the sample is located at a defined distance from the horn face. However, the tip of the sonotrode also represents a wear body in this measurement.

For tests with indirect cavitation, it is important to ensure that the material damage progresses much more slowly than with direct cavitation tests; the tests can be run continuously and intermittently. In contrast to the continuous method, the intermittent method involves intermediate measurements. This makes it possible to determine whether the wear increases linearly or non-linearly. Before and after the test the sample is cleaned, dried and weighed. In addition, tests on the surface values Ra and Rz, the Abott contact ratio curve and other material-related tests can be carried out by agreement. As test conditions deviating from the standard, the temperature and the medium, the test time and the shape of the sonotrode tip can be varied by agreement.